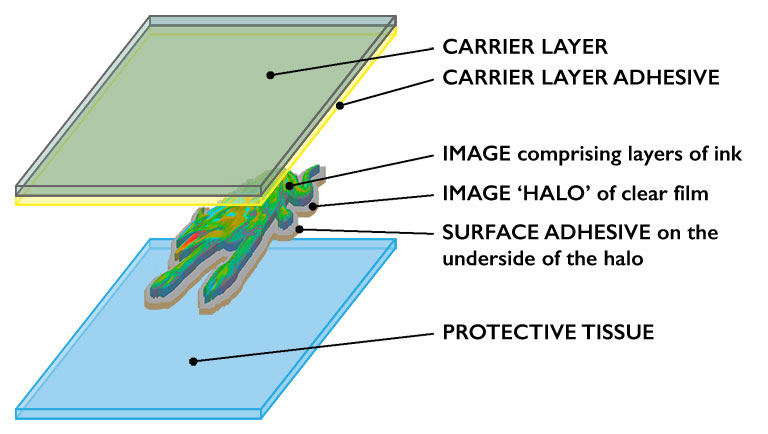

On this page, we're going to look at how dry transfers are put together:

The Anatomy of a Transfer

Letraset transfers (& other transfers, generally) consist of several layers of material:

- a clear plastic CARRIER LAYER, which is disposable once the transfer image has been applied

- the CARRIER LAYER ADHESIVE or wax, temporarily binding the image to the carrier layer

- the IMAGE itself (which may, in turn, comprise several printed ink layers)

- the IMAGE HALO, a clear film on which the image is printed

- the SURFACE ADHESIVE on the underside of the image halo, to bond the image permanently to the recipient surface

- a waxed paper PROTECTIVE TISSUE, to prevent the image accidentally transferring prematurely.

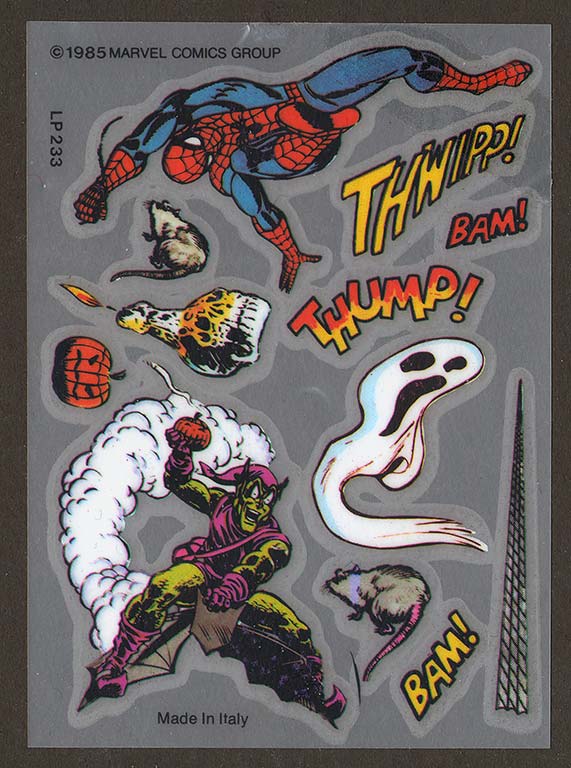

What does the protective tissue look like in real life? Here you go:

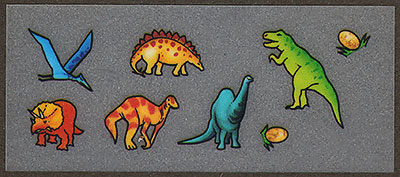

Traditionally, Letraset protective tissues had a distinctive blue colour; in later years, they were more often a neutral grey. Here is a small, recent, transfer both with & then without its protective tissue:

Lastly, the carrier sheet is turned back-to-front so you can see a couple of features of the transfer itself.

Firstly, notice that there is a white background layer of ink behind the artwork (apart from at the edges, which are borders of black ink). This is to give the colours an even background, & to help combat transparency. You don't want the recipient surface to be visible behind the transfer once you've applied it; transfers should normally be opaque!

Of course, this white background is not necessary with monochrome transfers. Because process colour transfers do require white ink, the inks are sometimes referred to as CMYKW (Cyan — Magenta — Yellow — blacK — White).

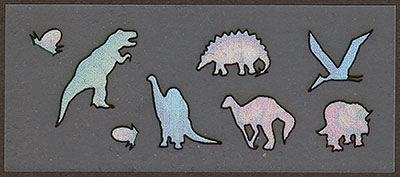

Secondly, if you look REALLY closely, you may just be able to glimpse the halo outside the black borders of the individual transfers. It's more obvious in some places than in others, but since the halo is intended to be completely transparent, it is necessarily hard to show. You might be able to make out that the area around the black borders is plainer & less textured than the general surrounding area.

To take pity on your eyes, here's a clearer example where the halo is easy to spot:

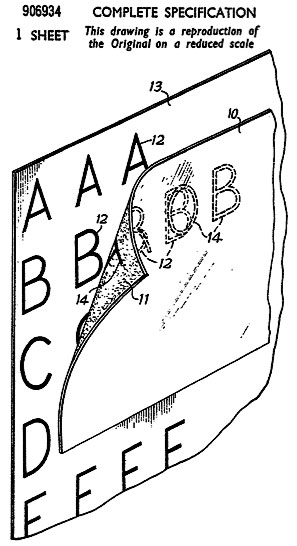

Letraset's Original Patent from 1959

Patent documents are inevitably somewhat dry, & I'm sure you don't want to read the whole application. Here are some extracts, along with the solitary diagram. The interesting points are that the patent is very limited to start with in its intended scope, & that at the point the application was made, Letraset clearly hadn't worked out all the details of the final product.

Oh, & also noteworthy is that the patent application talks quite a lot about musical notation; that didn't really turn out to be one of the big applications for the technology (but see the bottom of this page)…

The original text of the patent application appears below in italics, with my notes interpolated.

"The receptor sheet 10 is placed in contact with the carrier sheet 13 in the required position, using the guide lines 14 imprinted thereon, with the tacky coating 11 contacting the design indicia 12 printed on the carrier sheet 13. One of the design indicia 12 is then transferred by pressure using the finger-nail or any hard instrument commonly used for burnishing. The receptor sheet 10 is then pulled out of contact, and by its adhesive nature will cause the indicia 12 to be removed from the carrier sheet and retained on the coating 11. By movement of the receptor sheet and repetition of the process the required wordings may be composed. The indicia are arranged on the carrier sheet in one order, e.g. alphabetical order, but are reassembled on the receptor sheet in any required different order."

- NOTE: the product described above is completely different from Letraset's final product. Instead of the carrier sheet being applied to the recipient surface (i.e., instead of rubbing down the transfers by applying pressure FROM ABOVE through the other side of the carrier sheet), Letraset appear to have had in mind an additional special "receptor sheet" of plastic film which would be applied to the carrier sheet (i.e., the pressure would be applied through the receptor sheet FROM BELOW, which would be like rubbing your paper onto the transfers instead of rubbing your transfers onto the paper); not only the opposite way round from dry transfers as we known them today, but also severely limited in that the only suitable surface onto which characters could be transferred is this "receptor sheet" — interpolating what would turn out to be a quite unnecessary extra stage into the process.

"For completion, the receptor sheet may have the wax coating 11 neutralised by the application of a wax polish… Alternatively the receptor sheet, which may be a plastic film, may be placed on a base material and laminated thereto by means of pressure or burnishing."

- NOTE: not only is the plastic receptor sheet a redundant step in itself, it also poses the problem of how to clean the wax coating off it. This problem was solved in the event by only applying adhesive to the characters (or in colour transfers, to the halo). It's also worth pointing out that here it is the adhesive that sticks the characters to their final recipient surface (or receptor sheet) — nowadays called the surface adhesive — which is described as waxy, whereas in the final product it's the other adhesive — the carrier layer adhesive, which holds the images to the carrier layer — which is a wax.

"As noted above, instead of the waxy adhesive being applied to the receptor sheet it may be applied to the carrier sheet. The indicia may then be covered by a non-bonding cover film until required for use. The method of transfer is essentially the same."

- NOTE: this is a step in the right direction; putting the wax on the carrier sheet means fewer limitations as to what could be used as a receptor sheet. This also introduces the idea of the protective tissue for the first time.

"The thickness of the parts, especially of the waxes, is shown much exaggerated in the drawing.

"WHAT WE CLAIM IS: —

"1. A dry transfer material which comprises a coated carrier sheet having printed thereon a plurality of design indicia formed of a film-forming ink, the coating on the carrier sheet and the material of the design indicia being such that the the design indicia may be transferred bodily to a receptor sheet, and made adherent thereto by a layer of waxy adhesive located on the surface of the printed carrier sheet or on the surface of the receptor sheet, on application of substantial pressure to the design indicia, the waxy adhesive being made to adhere only by the application of such pressure and providing adhesive forces greater than the forces holding the design indicia to the coating on the carrier sheet."

- NOTE: when they put it like that, it does sound somewhat nearer to the final product. The only bit that's still a bit dodgy is the idea that a special receptor sheet would be required. If you allow practically anything hard & flat to count as a receptor sheet, then you have dry rub-down transfers as we know them.

The Letraset Recipe

To sum up: what makes Letraset transfers work is the following recipe —

- Light adhesive to hold the transfers onto the carrier sheet (Carrier Layer Adhesive);

- Strong adhesive to fix the transfers to the recipient surface (Surface Adhesive).

That's the main event. Here are the other ingredients:

- You need a protective tissue which the surface adhesive can't stick to.

- You need a carrier sheet that's transparent, so you can see the transfers through it (& see what you're doing).

- The carrier sheet needs to respond to pressure (& heat) by buckling, so that the transfers, which do NOT buckle, are forcibly detached when it buckles.

- You need to PRINT the Surface Adhesive onto the bottom of the transfer image (or its halo), so that you don't get nasty sticky glue anywhere else.

- Job done.

To find out more about Instant Lettering, & even see a sheet of music notation symbol transfers (as mentioned above), visit our page:

Other Letraset Products: Instant Lettering — Symbols →Here are the links to those "What are Transfers?" article pages again in full:

- "What are Transfers?" (Main Page) ↑

- Temporary Tattoos, including "How to Apply a Vintage 1960s Temporary Tattoo" →

- How to Apply a Waterslide Model Kit Transfer →

- Waterslide Transfers Applied to Drinking Glasses; plus Golly Transfers →

- The Letraset Type Lettering System →

- How to Apply Vintage 1959 Letraset Waterslide Lettering →

- Letraset's dry rub-down "Instant Lettering" →

- Heat Transfers, including "How to Apply a Vintage 1970s Iron-On Transfer" →

- How to Apply Letraset Dry Rub-Down Transfers →

- How Dry Rub-Down Transfers Work (this page; see above ↑)

- Topps Rub-Offs, Hasbro Rub-Ons, & Trans-Action →

- Some Lovely Décalcomanies →

- How to Apply a Sticker (& other Sticker treats) →

- Stick'N'Lift →